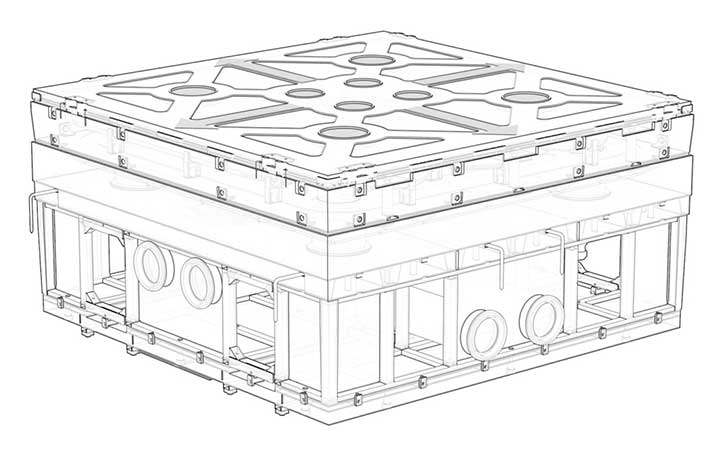

The First Fully Automated Construction System

For a better Understanding of Auto Construction check out our AECROS Robotics Solution

Building the future with blockchain robotic automation

What does a new industry look like? The best comparison we have…

Henry Ford created mass production so that everyone could have a car. This created the auto-motive industry.

At ACBM we are using mass production so that everyone can have a home. This creates the Auto-Construction industry.

Lifetimes of construction experience combine to create a new solution

Analysis.

High Grade Modern Construction

Engineering.

Engineered into building modules (NFTs)

Robotics.

Rapidly Assembled by robots

Fintech.

Financed with Crypto

Auto Construction

Building Homes

80X Faster

The first construction industry with robotic automation at its core Auto Construction associates a new Industry of technology partners and their support networks. This association (ACA) aligns the interests of these stakeholders in the pursuit of end to end construction automation. Each partner has an important role to play, but the industry does not rest solely on a single entity. Even as many new partners enter the space, the industry will honor its membership program globally.

Purchase MP TokensEnd to End construction: Automated

In same way that Henry Ford automated transportation and automobile production, Auto Construction is automating home construction, financing and development to create a whole new industry.

Volume of Value

Homes and buildings represent the largest purchases most people will ever make. Typical large transaction volumes of AEC(R) increase the importance, velocity, and permanence of technological adoption.

Learn More

Cascading Improvements

Manual construction AEC(R) is slow and inefficient. The keys to changing these multi-trillion dollar industries are in a single block. To change the ubiquitous building unit is to change the foundations of the AEC(R) industries.

Learn More

To Change Performance, Change the DNA

The redesign of the fundamental building unit to adapt the building method to robotics and financial technology is to change the DNA of AEC(R). To utilize software technology to fund, trade, design, and build within this paradigm creates a new world industry.

Learn MoreAdvanced technology makes Auto Construction possible

- AUTOPILOT

- NIGHT VISION

- TRIPPING SENSORS

- PRESSURE SENSORS

- ONGOING INVENTORY

- GYROSCOPIC LEVELLERS

- COMPUTER TARGETING SYSTEM

- ON SCREEN ENHANCED GRAPHICS

- COMPUTERIZED REMOTE SUPERVISION UI

- PROXIMITY ACTIVATED SPEED REDUCTION (LASERS)

- STABILIZING HARDWARE & SOFTWARE (AUGMENTED REALITY)

- COMPONENT PROOFS OF LOCATION (SATELLITES, BEACONS AND BLOCKCHAIN)

- SITE MAPPING PHASE SPACE POINT CLOUDS, AR AND DISTRIBUTED DATA PROCESSING

"We had no idea anyone was this far ahead. We will be excited to see this system in operation, and we will be your biggest customer."

Commuting Home in the Near Future

Lilium Electric Jets takeoff vertically (with no runway), carry six passengers and travel at 300 KM per hour. All this with zero pollution and no noise!

New access to formerly remote development locations.

Imagine bringing home the groceries, JETSONS style!

Phase Space Glove Controller To Handle Heavy Lifting On The Worksite

Distributed-processing motion tracking system for tracking individually modulated light points

Disclosed is a distributed-processing motion capture system (and inherent method) comprising: plural light point devices, e.g., infrared LEDs, in a motion capture environment, each providing a unique sequence of light pulses representing a unique identity (ID) of a light point device; a first imaging device for imaging light along a first and second axis; and a second imaging device for imaging light along a third and fourth axis. Both of the imaging devices filter out information not corresponding to the light point devices, and output one-dimensional information that includes the ID of a light point device and a position of the light point device along one of the respective axes.

The system also includes a processing device for triangulating three-dimensional positions of the light point devices based upon the one-dimensional information. The system is very fast because the necessary processing is distributed to be maximally parallel. The motion capture system uses a cylindrical collimating (CC) optics sub-system superimposed on a cylindrical telecentric (CT) optics sub-system. The outputs of the plural light point devices are modulated to provide a unique sequence of light pulses representing a unique identifier (ID) for each of the light point devices according to a predetermined cycle of modulation intervals based upon synchronization signals provided via RF communication. At least two of the light point devices concurrently provide light during the cycle.

Tracy D McSheery (San Mateo, CA) Black, John R. (Davis, CA) Nollet, Scott R. (Riverside, CA) Johnson, Jack L. (San Diego, CA) Jivan, Vinay C. (Milpitas, CA)

Everyone Deserves a Home

Henry Ford was a pioneer in his field, creating mass production and making it possible for everyone to have a car. A car is more than just a mode of transportation, it is freedom. In the same way that Ford created the automobile industry, AutoConstruction is creating a futuristic way to make housing attainable for everyone.

By combining mass production with advanced robotics and automation processes, we are working to redefine the construction industry to be more efficient, less wasteful and more accessible.

Automated Construction: Modernizing Outdated Methods

The traditional manual construction process is slow and dependent on a variety of factors, from material costs and permitting, and can be impacted by something as simple as a labor shortage. A machine with robotic arms is not your average construction worker. They never get tired, they never need time off, and they run off of in-depth information modelling to ensure that each piece of material is laid properly, according to building codes.

Advanced construction robotics and industrial robots are paving the way and laying the foundation for increased productivity within the industry. These new construction technologies are able to create a more streamlined mode of building. Supply chains are eliminated, as blocks are made without the need of an international manufacturing facility, and processes are not at the mercy of the elements, labor issues and can help to mitigate unforeseen budgetary spikes.

Construction is slow, and messy.

We can do better.

Construction Innovation

As a whole, the construction industry is wasteful. Manual building construction is subject to human error, which can lead to a higher cost of repair, a shorter lifespan for your structures and can result in higher material costs when aspects of projects need to be redone.

The world of automation and digital construction seeks to eliminate these obstacles. In the same way that a construction site relies on heavy equipment to get the job done, automated construction creates hurricane and fire resistant structures through the use of a robotic crane. These cranes lift constructed blocks that fit tightly together, in much the same way that Lego blocks might.

The AutoConstruction methodology not only reduces the risk of setbacks and the possibility of budget spikes, but also makes turn-around times that much quicker, without sacrificing quality. For many individuals, robotic construction projects are restricted to 3D printing buildings, but industry innovation has come much further than that, both in practice and in payments.

"Automated Construction and Blockchain were made for each other … we just didn’t know it yet" - Aecros Dev Team

Tokenization and Auto Construction: Partners in the Future of Construction

Part of what slows construction projects, are accessible payments. Many site managers are forced to chase down vendors, seeking out funds, which delays production. Instead of holding up construction projects, AutoConstruction is able to keep building on target with tokenization. Cryptocurrency is the wave of the future, so it makes sense to partner this futuristic currency, with a futuristic take on building.

An MP is a fungible ERC 20 Token on the Ethereum blockchain. Block NFT’s are the future of construction and will only rise in value over time. Instead of sitting idle, these Tokens are traded on the Block Exchange (BEX), to be used for robotic cranes and construction materials. Each of these NFTs are tethered to a physical block. Once the block is constructed, the physical block is shipped for use and the digital NFT is used.

By creating a form of currency that does not have to be converted or sourced, and making it affordable, AutoConstruction is hoping to help provide a safe and comfortable home for every body.

"Auto Construction engineers were busy streamlining construction with Modules and assembly systems when crypto came along offering new solutions that we could never even have dreamed of... it was quite the AHA! moment."